IR MUSIC TRANSMITTER AND RECEIVER

PRADEEP G.

Using this circuit, audio musical notes can be generated and heard up to a distance of 10 metres.

The

circuit can be divided into two parts: IR music transmitter and

receiver. The IR music transmitter works off a 9V battery, while the IR

music receiver works off regulated 9V to 12V. Fig. 1 shows the circuit

of the IR music transmitter. It uses popular melody generator IC UM66

(IC1) that can continuously generate musical tones. The output of IC1 is

fed to the IR driver stage (built across the transistors T1 and T2) to

get the maximum range.

Fig. 1: Transmitter circuit

Here the red LED (LED1) flickers according to the musical tones generated by UM66 IC, indicating modulation. IR LED2 and LED3 are infrared transmitting LEDs. For maximum sound transmission these should be oriented towards IR phototransistor L14F1 (T3).

The IR music receiver uses popular op-amp IC µA741 and audio-frequency amplifier IC LM386 along with phototransistor L14F1 and some discrete components (Fig. 2).

Fig. 2: IR audio receiver circuit

The

melody generated by IC UM66 is transmitted through IR LEDs, received by

phototransistor T3 and fed to pin 2 of IC µA741 (IC2). Its gain can be

varied using potmeter VR1. The output of IC µA741 is fed to IC LM386

(IC3) via capacitor C5 and potmeter VR2. The melody produced is heard

through the receiver’s loudspeaker. Potmeter VR2 is used to control the

volume of loudspeaker LS1 (8-ohm, 1W). Switching off the power supply

stops melody generation.

___________________________________________________________________________________

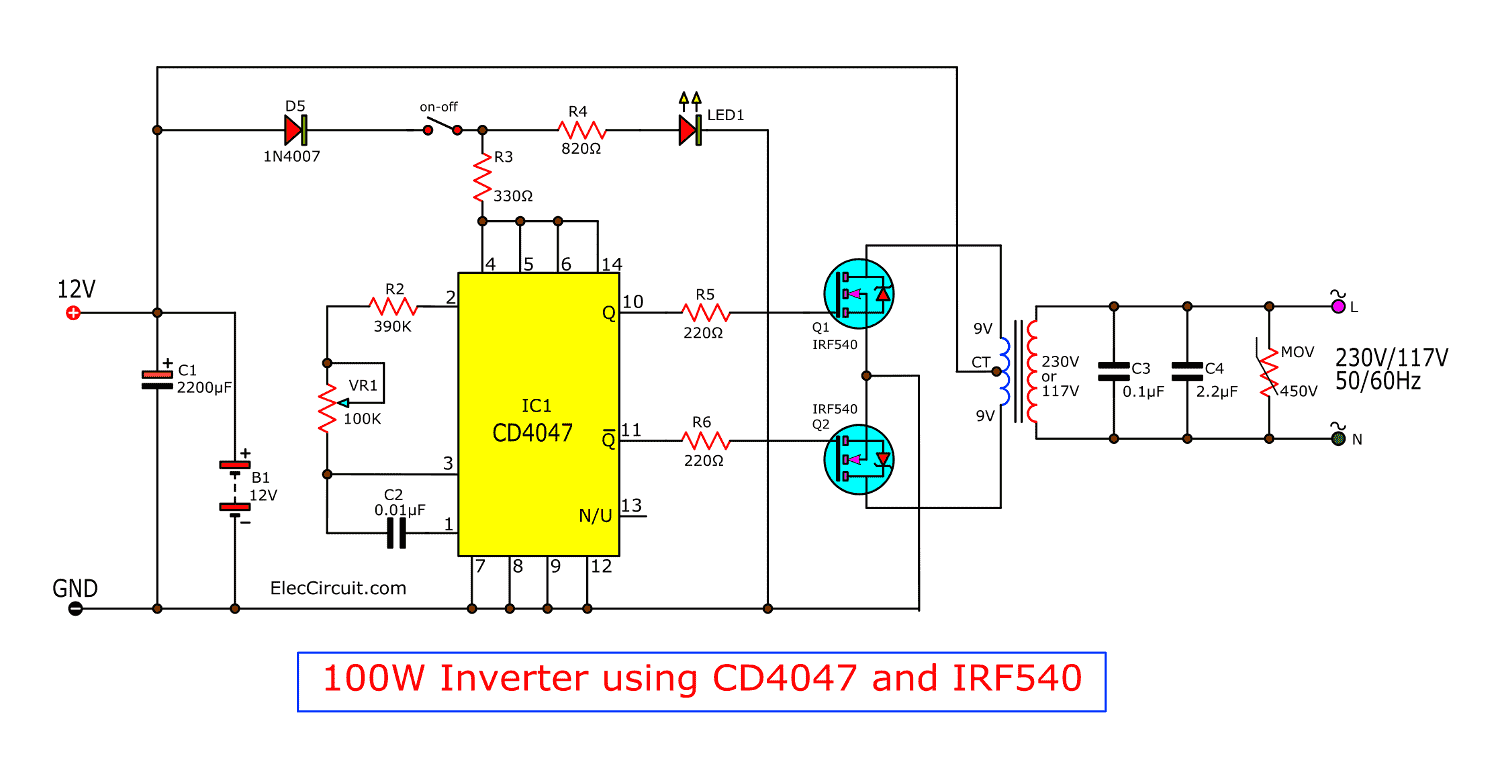

mini inverter diagram

Hi,__________________________________________________________________

In the PM, you had asked for a better circuit. Here is one:

Something with SG3525 would be nicer, but this will do quite well. You could change the MOSFET gate resistors to 22ohm.

Look here:

12V DC to 220V 100W Inverter with 4047 IC & IRF540

Hope this helps.

Tahmid.

Programmable Home Security Alarm System

author: Dilshan R Jayakody -

jayakody2000lk gmail.com

gmail.com

author: Dilshan R Jayakody

< sub>

Introduction

|

In this project we design low cost high performance programmable

home security system and there is no need to contact a company like

Safemart home security

for setup. This system uses a few LDR's as input sensors.

When above sensor(s) get triggered system may dial the user

specified phone number (using build-in DTMF generator) and activate

the high power audio alarm and lights. All the parameters of DTMF generator,

audio alarm and light interface are programmed through the RS232 serial interface.

Current firmware of this system presents interactive control system through the RS232 interface. This control system consist with the menu driven configuration options, self tests, system report generators, etc.

This system also contain 5W (with 4Ω speaker) audio alarm with three selectable tone configurations, which include Police siren, Fire engine siren and Ambulance siren.

Current firmware of this system presents interactive control system through the RS232 interface. This control system consist with the menu driven configuration options, self tests, system report generators, etc.

This system also contain 5W (with 4Ω speaker) audio alarm with three selectable tone configurations, which include Police siren, Fire engine siren and Ambulance siren.

System Features

|

- Touch tone phone dialing

interface

- 5W High powerful audio alarm

- 2 sensor interface with separate sensitivity adjustments

- Programmed through the RS232 interface

- Build-In intelligent light ON/OFF switch

- 5W High powerful audio alarm

- 2 sensor interface with separate sensitivity adjustments

- Programmed through the RS232 interface

- Build-In intelligent light ON/OFF switch

Integrated Circuits

|

This system

uses a Microchip's PIC16F877A as a main controller,

LM339 as sensor interface, UM3561 as a tone

generator and μPC2002 as a speaker driver (audio

amplifier). LM7805, LM7812 and LM317 voltage

regulators are used to obtain +5V, +12V and +3V

respectively.

Assembly

|

Fig.1 - Connectors, Jumpers and other controls of the Programmable Home

Security Alarm System

The PCB design given with this

article makes the assembly much simpler. As PCB contain 230V AC main

lines care must be taken while assembling the circuit. As shown in the

fig.1 all the photoelectric sensors, some of the switches and alarm

speaker are connected with the circuit through the connector bars.

|

External connectors and controls |

DC

Power input : Attach DC power supply with

18V - 25V (2A Max.) output.

RS232 Connector : Connect RS232 serial cable to the port to configure the system. Do not use RS232 Null Modem cable with this port.

PHONE/LINE connector : Attach standard RJ12/RJ11 telephone cable connector to this port. One port is need to use with the phone line and remaining port is for the phone (and it is optional).

3V LASER supply : 3V supply line for LASER diode assembly.

Connectors for Sensor 1/2 : Attach high sensitive LDRs for these ports. To get the maximum sensitivity it is recommended to use EG&G VACTEC LDRs.

Status Indicator : Indicate run, program and sensor trigger modes.

Reset Switch : Press this button to reset entire alarm system. This button enable only when the audible alarm get activated. It is not possible to use this function at the phone dialing/ringer states.

Phone dialer enable switch : Turn on this switch to enable the phone dialing feature of this system. Environment Sensor : In-circuit LDR to detect light conditions of the environment.

Alarm Volume Control : Use this to control the output power (volume) of the audible alarm.

230V Light connector : Attach 230V AC light (or related peripheral) to these terminals.

Tone Selector : Configure the master alarm tone from this jumper as follows,

1-2 : Fire Engine Siren

2-3 : Ambulance Siren

Open : Police Siren

(Do not connect jumper terminal 1-3, this combination may permanently damage the entire system) Beeper : Produce beeps (e.g: at the input error, etc.)

Program / Run Switch connector : Attach switch to this header to select Program or Run mode.

Alarm Audio Output : Attach 8Ω (8W) or 4Ω (10W) speaker to this connector.

RS232 Connector : Connect RS232 serial cable to the port to configure the system. Do not use RS232 Null Modem cable with this port.

PHONE/LINE connector : Attach standard RJ12/RJ11 telephone cable connector to this port. One port is need to use with the phone line and remaining port is for the phone (and it is optional).

3V LASER supply : 3V supply line for LASER diode assembly.

Connectors for Sensor 1/2 : Attach high sensitive LDRs for these ports. To get the maximum sensitivity it is recommended to use EG&G VACTEC LDRs.

Status Indicator : Indicate run, program and sensor trigger modes.

Reset Switch : Press this button to reset entire alarm system. This button enable only when the audible alarm get activated. It is not possible to use this function at the phone dialing/ringer states.

Phone dialer enable switch : Turn on this switch to enable the phone dialing feature of this system. Environment Sensor : In-circuit LDR to detect light conditions of the environment.

Alarm Volume Control : Use this to control the output power (volume) of the audible alarm.

230V Light connector : Attach 230V AC light (or related peripheral) to these terminals.

Tone Selector : Configure the master alarm tone from this jumper as follows,

1-2 : Fire Engine Siren

2-3 : Ambulance Siren

Open : Police Siren

(Do not connect jumper terminal 1-3, this combination may permanently damage the entire system) Beeper : Produce beeps (e.g: at the input error, etc.)

Program / Run Switch connector : Attach switch to this header to select Program or Run mode.

Alarm Audio Output : Attach 8Ω (8W) or 4Ω (10W) speaker to this connector.

|

Calibration and Testing |

Once

everything is assembled take following steps to

calibrate the system,

1. Remove IC1, IC2, IC3 and IC4 from the IC bases.

2. Apply 18V ( to 22V Max.) DC source to the power connector (J3).

3. Check the voltage between Pin12 (GND) and Pin3 of IC2. It need to be 4.8V - 5.1V DC.

4. Check the voltage between GND and E$4 jumper. It need to be 11.7V - 12.3V DC.

5. Check the voltage between Pin1 and Pin3 (GND) of JP1. It need to be 2.5V - 3.1 V

6. If all the above Step 3, 4 and 5 are correct, disconnect the power supply and insert IC1, IC2, IC3 and IC4 in to the appropriate IC bases. Attach suitable speaker to the X4 and connect RS232 cable to the system.

7. Close the jumper J2 (Program Mode) and power on the system.

8. Download and install PuTTY on to the target computer and setup the "Serial" connection with 9600 baud rate (see Fig. 3).

1. Remove IC1, IC2, IC3 and IC4 from the IC bases.

2. Apply 18V ( to 22V Max.) DC source to the power connector (J3).

3. Check the voltage between Pin12 (GND) and Pin3 of IC2. It need to be 4.8V - 5.1V DC.

4. Check the voltage between GND and E$4 jumper. It need to be 11.7V - 12.3V DC.

5. Check the voltage between Pin1 and Pin3 (GND) of JP1. It need to be 2.5V - 3.1 V

6. If all the above Step 3, 4 and 5 are correct, disconnect the power supply and insert IC1, IC2, IC3 and IC4 in to the appropriate IC bases. Attach suitable speaker to the X4 and connect RS232 cable to the system.

7. Close the jumper J2 (Program Mode) and power on the system.

8. Download and install PuTTY on to the target computer and setup the "Serial" connection with 9600 baud rate (see Fig. 3).

9. Press "2" and enter into the "Parameter Setup" mode.

Configure all the parameter options with the appropriate settings.

10. Attach phone line to the PHONE/LINE connector and fix photoelectric LDR sensors to the X1 and X2 connectors.

10. Attach phone line to the PHONE/LINE connector and fix photoelectric LDR sensors to the X1 and X2 connectors.

Fig.2 - DTMF output generated by the system at the testing stages. (Test

points : TRN1 input terminals)

11. Press "3"

and execute "Self Test".

12. Adjust R4*, R6* and R8* preset controls, if the sensors are not trigged as expected.

13. Adjust R11 preset to control the "Day" and "Night" mode detection.

14. Open the Jumper J2 and press 5 to return to the Run mode.

15. Shutdown the power supply and disconnect the RS232 cable.

12. Adjust R4*, R6* and R8* preset controls, if the sensors are not trigged as expected.

13. Adjust R11 preset to control the "Day" and "Night" mode detection.

14. Open the Jumper J2 and press 5 to return to the Run mode.

15. Shutdown the power supply and disconnect the RS232 cable.

Fig.3 - PuTTY configuration setup for Programmable Home Security Alarm

System

* R6 - X1 sensor sensitivity, R8 - X2 sensor sensitivity, R4 - sensor

gain controller (Common mode)

Download

|

Schematic

|

Click for higher resolution

PCB

|

Download Parts Layout in PDF format

Download PCB in PDF format

http://www.electronics-lab.com/projects/sensors/008/index.html

for reference go for above address

___________________________________________________________________________________

ELECTRONIC SECURITY SYSTEM

Fig. 1: Monitoring circuit along with the alarm circuit

Fig. 2: Physical layout of sensors and monitoring alarm system

You can alter the alarm sound as desired by changing the connections of IC1 as shown in the table.

for reference go for above address

___________________________________________________________________________________

Pocket Pager Engineering Circuit Diagram Example - SmartDraw

ELECTRONIC SECURITY SYSTEM

K. BHARATHAN

This

reliable and easy-to-operate electronic security system can be used in

banks, factories, commercial establishments, houses, etc.

The

system comprises a monitoring system and several sensing zones. Each

sensing zone is provided with a closed-loop switch known as sense

switch. Sense switches are fixed onthedoors of premises under security

and connected to the monitoring system. As long as the doors are

closed, sense switches are also closed. The monitoring system can be

installed at a convenient central place for easy operation.

Fig.

1 shows the monitoring circuit only for zone 1 along with the common

alarm circuit. For other zones, the monitoring circuit is identical,

with only the prefixes of components changing as per zone number.

Encircled points A, B, and C of each zone monitoring circuit need to be

joined to the corresponding points of the alarm circuit (upper half of

Fig. 1).

Fig. 1: Monitoring circuit along with the alarm circuit

When

zone 1 sensing switch S11, zone switch S1 are all on, pnp transistor

T12 reverse biases to go in cut-off condition, with its collector at

around 0 volt. When the door fitted with sensor switch S11 is opened,

transistor T12 gets forward biased and it conducts. Its collector

voltage goes high, which forward biases transistor T10 via resistor R10

to turn it on. (Capacitor C10 serves as a filter capacitor.) As a

result, the collector voltage of transistor T10 falls to forward bias

transistor T11, which conducts and its collector voltage is sustained

at a high level. Under this latched condition, sensor switch S11 and

the state of transistor T12 have no effect. In this state, red LED11 of

the zone remains lit.

Simultaneously, the high-level voltage from the collector of transistor T11 via diode D10 is applied to VDD pin 5 of siren sound generator IC1 (UM3561) whose pin 2 is grounded. Resistor R3 connected across pins 7 and 8 of IC1 determines the frequency of the in-built oscillator. As a result, IC1 starts generating the audio signal output at pin 3. The output voltage from IC1 is further amplified by Darlington pair of transistors T1 and T2. The amplified output of the Darlington pair drives the loudspeaker whose output volume can be controlled by potentiometer VR1. Capacitor C1 serves as a filter capacitor.

Simultaneously, the high-level voltage from the collector of transistor T11 via diode D10 is applied to VDD pin 5 of siren sound generator IC1 (UM3561) whose pin 2 is grounded. Resistor R3 connected across pins 7 and 8 of IC1 determines the frequency of the in-built oscillator. As a result, IC1 starts generating the audio signal output at pin 3. The output voltage from IC1 is further amplified by Darlington pair of transistors T1 and T2. The amplified output of the Darlington pair drives the loudspeaker whose output volume can be controlled by potentiometer VR1. Capacitor C1 serves as a filter capacitor.

Fig. 2: Physical layout of sensors and monitoring alarm system

You can alter the alarm sound as desired by changing the connections of IC1 as shown in the table.

The

circuit continues to sound the alarm until zone door is closed (to

close switch S11) and the reset switch is pressed momentarily (which

causes transistor T10 to cut off, returning the circuit to its initial

state).

The

system operates off a 3V DC battery or recharging battery with charging

circuit or battery eliminator. If desired, more operating zones can be

added. Initially keep the monitoring system switch S1 off. Keep all the

zone doors fixed with sensing switches S11, S21, S31, S41, etc closed.

This keeps the sensing switches for respective zones in closed

position. Also keep zone slide switches S12, S22, S32, S42, etc in ‘on’

position. This puts the system in operation, guarding all the zone

doors.Now, if the door of a particular zone is opened, the monitoring

system sounds an audible alarm and the LED corresponding to the zone

glows to indicate that the door of the zone is open. The alarm and the

LED indication will continue even after that particular door with the

sensing switch is immediately closed, or even if that switch is

removed/damaged or connecting wire is cut open. Any particular zone in

the monitoring system can be put to operation or out of operation by

switching on or switching off the corresponding slide switch in the

monitoring system.

__________________________________________________________________________________

CORDLESS SECURITY SYSTEM

MINI PROJECT REPORT

Submitted in partial fulfillment of the requirements for the award of the degree of B.TECH IN APPLIED ELECTRONICS & INSTRUMENTATION from THE UNIVERSITY OF KERALA

By

SABARINATH P M

RENJITH E R

NIEL V JOSEPH

S6 Applied Electronics And Instrumentation,

COLLEGE OF ENGINEERING TRIVANDRUM

front sheet3.doc (Size: 1.33 MB / Downloads: 160)

front sheet3.doc (Size: 1.33 MB / Downloads: 160)

INTRODUCTION

Nowadays more effort and work is done to make security system defect less, reliable and intelligent. Every loophole is identified and cleared. ËœCORDLESS SECURITY SYSTEM Ëœis such an effort which is a highly improved version of present security system.

With the breach of security, the owner is alarmed through an RF transmitter receiver system. Simultaneously some preventive and defensive action is triggered .

The project implements the security system in a car .Any theft attempt cause an alarm to sound in the remote held with the owner who maybe at a distance from the car. Moreover the system makes the engine temporarily nonfunctioning. An alarm also triggered in the vehicle.

But the key striking feature is that it is highly economical. It is compact in size, consumes very little power and user friendly.

FEATURES

Low cost and high reliability

Consume very little power

User friendly

Range of up to 75 meters.

APPLICATION

Security breach has become a serious problem today. So it is essential to update ations the present system. Cordless security system is a right choice. It can be implemented in a home, museum or even a bank for it provides great reliability. Unlike most of the present system it has much more key features like alarming the owner who maynot be near the site and also ensures the prevention of the theft in any case.Can be installed in the locker rooms of banks as it is highly reliable.Its highly viable as it can be modified with ease according to place where it is implemented.If in case of security of car it switches off the battery temporirly,in case of home system it is modified to alert the neighbour and police.Thus its applications are wide and practical.

CONTENTS

Introduction

Features and Application

Block Diagram and Description

Circuit Diagram

Circuit description and working

PCB Fabrication

Assembly and Testing

Schedule

Conclusion

Reference

Datasheets

TRIGGERING AND TRANSMISSION:

The initial part of the security system consists of three parts.

SCR SWITCH:Any theft attempt triggers the scr switch to fire.This triggers corresponding relays. First one is a simple scr switch from the door. When door opens it will open and when door is closed it is also closed. Scr switch which is normally in off state. When someone opens the door scr circuit is triggered.

RELAY NETWORK: Scr triggering causes three relays to on state.One of them is coupled to the encoder circuit for transmission.The other one cuts-off the battery of the car temporarily.Final relay in the initial section causes an alarm to sound .

RF TRANSMITTER

For transmission an RF transmitter module is used .The module requires an encoder HT12E which is shown in the block diagram.The encoder is required to convert parallel data to serial before it is given to the transmitter .The address pins are also specified.Transmitter uses a frequency of 434Mhz and transmits digital data.An antenna is used to increase the range of transmission.Range of upto 75 meters is practically obtained.

RECEIVER AND RESPONSE SYSTEM:

RECEIVER AND DECODER:The receiver data pin receives the digital data transmitted and this serial data is decoded by HT12D to obtain the parallel data out.Here only one of the data pin of the decoder output is used.This is high in case of any theft attempt and it sounds an alarm . Within a range upto 50 meters the owner is alerted.

CIRCUIT DISCRIPTION AND WORKING

Here is an easy-to-build car anti-theft guard. The circuit, shown in Fig. 1, is simple and easy to understand.

When key-operated switch S2 of the car is turned on, 12V DC supply from the car battery is extended to the entire circuit through polarity-guard diode D5. Blinking LED1 flashes to indicate that the guard circuit is enabled. It works off 12V power supply along with current-limiting resistor R4 in series.

When the car door is closed, door switch S1 is in Ëœonâ„¢ position and 12V power supply is available across resistor R1, which prevents transistor T1 from conducting. In this position, antitheft guard circuit is in sleep mode.

When someone opens the car door, switch S1 becomes ˜off™ as shown in Fig.2. As a result, transistor T1 conducts to fire relay “driver SCR1 (BT169) after a short delay introduced by capacitor C1. Electromagnetic relay RL1 energizes and its N/O contact connects the power supply to piezobuzzer PZ1, which starts sounding to indicate that someone is trying to steal your car. To reset the circuit, turn off switch S2 using car key. This will cutoff the power supply to the circuit and stop the buzzer sound.

Connect switch S1 to the car door and keep piezobuzzer PZ1 at an appropriate place in the car.

But this sound will not be sufficient , when the owner is inside a building like a shopping complex or somewhere away from the car. For this we incorporated a Transmitter-Receiver circuit. The data sent from the car can be received by a receiver in the hand.

There is a relay2(RLA2) which grounds the input terminal (10) of the encoder(HT12E) to ground. ie, the input of the encoder is logically 0. This data is sent through the transmitter. When the receiver receives and decodes it with the decoder(HT12D) due to logic 0 output through the pin10 the piezobuzzer(PZ2) will not make any sound. When someone opens the car, the switch s1 is opened and the third relay will energized due to the activation of the scr circuit. Now the connection with ground is disconnected. So the input terminal of encoder is logically high. This data is transmitted . At the receiver this will make high output & hence the piezobuzzer (PZ2) starts to make sound. This will continue even when the door of car is closed. This sound will stop only when we switch of the receiver or switch when switch s2 is made off.

Also there is an extra security that when someone opens the car, the relay will energize and the third relay (RLA3) will break the ignition circuit - automatically immobilizing the vehicle. When the circuit is switched on again the relay will not energize; and the vehicle's ignition circuit will remain broken. You must press S2 to energize the relay. It then de-energizes the first relay (RLA1); while the third relay (RLA3) energizes and completes the connection to the ignition circuit.

The design of car immobilizer has a number of advantages. It requires only one extra relay(RLA3). It operates automatically when switch s2 for the transmitter circuit is turned on - so there's no need to remember to activate it separately. To de-activate it you'll need to have the ignition key and you'll need to know the whereabouts of the push-switch. S2 only requires a single wire because its return is through the chassis. It carries no load other than the current required by the relay-coil. So almost any small "momentary-action, push-to-make" switch will do. For extra security S2 could be key-operated.

DATA SHEETS

HT12E

Features

_ Operating voltage _ 2.4V~5V for the HT12A

_ 2.4V~12V for the HT12E _ Low power and high noise immunity CMOS technology

_ Low standby current: 0.1_A (typ.) at VDD=5V _ HT12A with a 38kHz carrier for infrared transmission medium

_ Minimum transmission word _ Four words for the HT12E

_ Built-in oscillator needs only 5% resistor _ Data code has positive polarity

_ Minimal external components _ HT12A/E: 18-pin DIP/20-pin SOP package

Applications

_ Burglar alarm system _ Smoke and fire alarm system

_ Garage door controllers _ Car door controllers

_ Car alarm system _ Security system

_ Cordless telephones _ Other remote control systems

General Description

The 212 encoders are a series of CMOS LSIs for remote control system applications. They are capable of encoding information which consists of N address bits and 12_N data bits. Each address/data input can be set to one of the two logic states. The programmed addresses/data are transmitted together with the header bits via an RF or an infrared transmission medium upon receipt of a trigger signal. The capability to select a TE trigger on the HT12E or a DATA trigger on the HT12A further enhances the application flexibility of the 212 series of encoders.

PIN DIAGRAM

ELECTRICAL DISCRIPTIONS

Functional Description

Operation

The 212 series of encoders begin a 4-word transmission cycle upon receipt of a transmission enable

(TE for the HT12E active low). This cycle will repeat itself as long as the transmission enable (TE or D8~D11) is held low. Once the transmission enable returns high the encoder output completes its final cycle and then stops as shown below.

Information word

If L/MB=1 the device is in the latch mode (for use with the latch type of data decoders). When the transmission

enable is removed during a transmission, the DOUT pin outputs a complete word and then

stops. On the other hand, if L/MB=0 the device is in the momentary mode (for use with the momentary

type of data decoders). When the transmission enable is removed during a transmission, the DOUT

outputs a complete word and then adds 7 words all with the _1_ data code.

An information word consists of 4 periods as illustrated below.

COMPOSITION OF INFORMATION

HT12D

Features

_ Operating voltage: 2.4V~12V _ Low power and high noise immunity CMOS technology

_ Low standby current _ Capable of decoding 12 bits of information

_ Binary address setting _ Received codes are checked 3 times

_ Address/Data number combination _ HT12D: 8 address bits and 4 data bits

_ Built-in oscillator needs only 5% resistor _ Valid transmission indicator

_ Easy interface with an RF or an infrared transmission medium

_ Minimal external components _ Pair with Holtek_s 212 series of encoders

_ 18-pin DIP, 20-pin SOP package

Applications

_ Burglar alarm system _ Smoke and fire alarm system

_ Garage door controllers _ Car door controllers

_ Car alarm system

_ Security system _ Cordless telephones

_ Other remote control system

General Description

The 212 decoders are a series of CMOS LSIs for remote control system applications. They are paired with Holtek_s 212 series of encoders (refer to the encoder/decoder cross reference table). For proper operation, a pair of encoder/decoder with the same number of addresses and data format should be chosen. The decoders receive serial addresses and data from a programmed 212 series of encoders that are transmitted by a carrier using an RF or an IR transmission medium. They compare the serial input data three times continuously with their local addresses. If no error or unmatched codes are found, the input data codes are decoded and then transferred to the output pins. The VT pin also goes high to indicate a valid transmission. The 212 series of decoders are capable of decoding informations that consist of N bits of address and 12_N bits of data. Of this series, the HT12D is arranged to provide 8 address bits and 4 data bits, and HT12F is used to decode 12 bits of address information.

FABRICATION OF PCB

The printed circuit board(PCB) provides the electrical interconnections various components and as well as provides mechanical support to the components.The components are soldered to the PCB.The quality of soldering directly affects the reliability of the circuit.The procedure for fabricating the PCB for any general project is described below.

¢ PCB MAKING

The making of PCB essentially involves two steps.

1.Preparing PCBdrawing

2.Fabricating PCB from the drawing.

¢ PCB Drawing

Making of PCB drawing involves placement of components , locating holes ,optimum area each componenet should occupy, shape and size of pads for the componenets , track size and spacing and prevention of overcrowding of components at a particular area. With these details the sketch of the PCB is made.

¢ PCB FABRICATION

The fabrication of the PCB starts by transferring the PCB drawing onto a copper clad sheet. For a small number of PCBs a direct photographic transfer of the PCB drawing from a negative image of the drawing to a photo sensitised copper clad sheet is carried out. The copper from the unexposed area is later etched away.

For large quantity production, screen printing method is used to transfer the PCB drawing image to the copper clad sheet. For etching the copper clad sheet 20-30grms of ferric chloride in 75ml of water heated to about 60degree celsius may be used . The copper clad sheet is placed in the solution with its copper side upwards in a plastic tray. Stirring the solution helps in speedy etching. The dissolution of unwanted copper would take about 45min. If etching takes longer, the solution may be heated again and the process is repeated. The paint on the pattern can be removed by rubbing with a rag soaked in thinner, turpentine or acetone. The PCB can then be washed and dried. The pads are drilled with proper drill sizes of 0.9mm,1mm,3mm etc for the leads and mounting holes

ASSEMBLY AND TESTING

Assembly consists of soldering of components and wires on to the PCB and mechanical fitting of wired PCB and other assemblies. Testing is carried out even at design phase itself in breadboard level to verify the design, so that little or no circuit changes are required after designing the PCB.

¢ Soldering

Before soldering, all the discrete components are tested. The leads of the components are cleaned with a fine abrasive paper. The PCB also thoroughly cleaned by scratching the areas to be soldered. The leads of the components are bend properly, inserted into the holes and placed correctly. A small quantity of flux is applied to the component leads and pads to remove the oxide coating. The leads are soldered with good quality solder with sufficient heat from the soldering iron. Excess heat will result in improper soldering and may damage the component.

All the joints are checked after the soldering.

¢ Testing

After soldering the components on to the PCB, the board is thoroughly cleaned for any residual flux and wire leads. All the components are checked for their value and for the proper orientation if applicable. Before ICs are inserted into the sockets, power applied to the board and voltages are measured at the IC power point. Power is switched off before the ICs are inserted.

SCHEDULE

1. Literature survey

2. Design of circuit

3. Testing of the circuit on breadboard

4. Modifying the circuit

5. Making pcb layout

6. Pcb fabrication

7. Soldering

8. Results obtained

CONCLUSION

Our product is suitable for bank, home and other security threat areas. Being cost effective and simple its application will be wide. Power consumption is very low which is a key feature. Many modifications can be easily implemented making it user friendly.

MINI PROJECT REPORT

Submitted in partial fulfillment of the requirements for the award of the degree of B.TECH IN APPLIED ELECTRONICS & INSTRUMENTATION from THE UNIVERSITY OF KERALA

By

SABARINATH P M

RENJITH E R

NIEL V JOSEPH

S6 Applied Electronics And Instrumentation,

COLLEGE OF ENGINEERING TRIVANDRUM

INTRODUCTION

Nowadays more effort and work is done to make security system defect less, reliable and intelligent. Every loophole is identified and cleared. ËœCORDLESS SECURITY SYSTEM Ëœis such an effort which is a highly improved version of present security system.

With the breach of security, the owner is alarmed through an RF transmitter receiver system. Simultaneously some preventive and defensive action is triggered .

The project implements the security system in a car .Any theft attempt cause an alarm to sound in the remote held with the owner who maybe at a distance from the car. Moreover the system makes the engine temporarily nonfunctioning. An alarm also triggered in the vehicle.

But the key striking feature is that it is highly economical. It is compact in size, consumes very little power and user friendly.

FEATURES

Low cost and high reliability

Consume very little power

User friendly

Range of up to 75 meters.

APPLICATION

Security breach has become a serious problem today. So it is essential to update ations the present system. Cordless security system is a right choice. It can be implemented in a home, museum or even a bank for it provides great reliability. Unlike most of the present system it has much more key features like alarming the owner who maynot be near the site and also ensures the prevention of the theft in any case.Can be installed in the locker rooms of banks as it is highly reliable.Its highly viable as it can be modified with ease according to place where it is implemented.If in case of security of car it switches off the battery temporirly,in case of home system it is modified to alert the neighbour and police.Thus its applications are wide and practical.

CONTENTS

Introduction

Features and Application

Block Diagram and Description

Circuit Diagram

Circuit description and working

PCB Fabrication

Assembly and Testing

Schedule

Conclusion

Reference

Datasheets

TRIGGERING AND TRANSMISSION:

The initial part of the security system consists of three parts.

SCR SWITCH:Any theft attempt triggers the scr switch to fire.This triggers corresponding relays. First one is a simple scr switch from the door. When door opens it will open and when door is closed it is also closed. Scr switch which is normally in off state. When someone opens the door scr circuit is triggered.

RELAY NETWORK: Scr triggering causes three relays to on state.One of them is coupled to the encoder circuit for transmission.The other one cuts-off the battery of the car temporarily.Final relay in the initial section causes an alarm to sound .

RF TRANSMITTER

For transmission an RF transmitter module is used .The module requires an encoder HT12E which is shown in the block diagram.The encoder is required to convert parallel data to serial before it is given to the transmitter .The address pins are also specified.Transmitter uses a frequency of 434Mhz and transmits digital data.An antenna is used to increase the range of transmission.Range of upto 75 meters is practically obtained.

RECEIVER AND RESPONSE SYSTEM:

RECEIVER AND DECODER:The receiver data pin receives the digital data transmitted and this serial data is decoded by HT12D to obtain the parallel data out.Here only one of the data pin of the decoder output is used.This is high in case of any theft attempt and it sounds an alarm . Within a range upto 50 meters the owner is alerted.

CIRCUIT DISCRIPTION AND WORKING

Here is an easy-to-build car anti-theft guard. The circuit, shown in Fig. 1, is simple and easy to understand.

When key-operated switch S2 of the car is turned on, 12V DC supply from the car battery is extended to the entire circuit through polarity-guard diode D5. Blinking LED1 flashes to indicate that the guard circuit is enabled. It works off 12V power supply along with current-limiting resistor R4 in series.

When the car door is closed, door switch S1 is in Ëœonâ„¢ position and 12V power supply is available across resistor R1, which prevents transistor T1 from conducting. In this position, antitheft guard circuit is in sleep mode.

When someone opens the car door, switch S1 becomes ˜off™ as shown in Fig.2. As a result, transistor T1 conducts to fire relay “driver SCR1 (BT169) after a short delay introduced by capacitor C1. Electromagnetic relay RL1 energizes and its N/O contact connects the power supply to piezobuzzer PZ1, which starts sounding to indicate that someone is trying to steal your car. To reset the circuit, turn off switch S2 using car key. This will cutoff the power supply to the circuit and stop the buzzer sound.

Connect switch S1 to the car door and keep piezobuzzer PZ1 at an appropriate place in the car.

But this sound will not be sufficient , when the owner is inside a building like a shopping complex or somewhere away from the car. For this we incorporated a Transmitter-Receiver circuit. The data sent from the car can be received by a receiver in the hand.

There is a relay2(RLA2) which grounds the input terminal (10) of the encoder(HT12E) to ground. ie, the input of the encoder is logically 0. This data is sent through the transmitter. When the receiver receives and decodes it with the decoder(HT12D) due to logic 0 output through the pin10 the piezobuzzer(PZ2) will not make any sound. When someone opens the car, the switch s1 is opened and the third relay will energized due to the activation of the scr circuit. Now the connection with ground is disconnected. So the input terminal of encoder is logically high. This data is transmitted . At the receiver this will make high output & hence the piezobuzzer (PZ2) starts to make sound. This will continue even when the door of car is closed. This sound will stop only when we switch of the receiver or switch when switch s2 is made off.

Also there is an extra security that when someone opens the car, the relay will energize and the third relay (RLA3) will break the ignition circuit - automatically immobilizing the vehicle. When the circuit is switched on again the relay will not energize; and the vehicle's ignition circuit will remain broken. You must press S2 to energize the relay. It then de-energizes the first relay (RLA1); while the third relay (RLA3) energizes and completes the connection to the ignition circuit.

The design of car immobilizer has a number of advantages. It requires only one extra relay(RLA3). It operates automatically when switch s2 for the transmitter circuit is turned on - so there's no need to remember to activate it separately. To de-activate it you'll need to have the ignition key and you'll need to know the whereabouts of the push-switch. S2 only requires a single wire because its return is through the chassis. It carries no load other than the current required by the relay-coil. So almost any small "momentary-action, push-to-make" switch will do. For extra security S2 could be key-operated.

DATA SHEETS

HT12E

Features

_ Operating voltage _ 2.4V~5V for the HT12A

_ 2.4V~12V for the HT12E _ Low power and high noise immunity CMOS technology

_ Low standby current: 0.1_A (typ.) at VDD=5V _ HT12A with a 38kHz carrier for infrared transmission medium

_ Minimum transmission word _ Four words for the HT12E

_ Built-in oscillator needs only 5% resistor _ Data code has positive polarity

_ Minimal external components _ HT12A/E: 18-pin DIP/20-pin SOP package

Applications

_ Burglar alarm system _ Smoke and fire alarm system

_ Garage door controllers _ Car door controllers

_ Car alarm system _ Security system

_ Cordless telephones _ Other remote control systems

General Description

The 212 encoders are a series of CMOS LSIs for remote control system applications. They are capable of encoding information which consists of N address bits and 12_N data bits. Each address/data input can be set to one of the two logic states. The programmed addresses/data are transmitted together with the header bits via an RF or an infrared transmission medium upon receipt of a trigger signal. The capability to select a TE trigger on the HT12E or a DATA trigger on the HT12A further enhances the application flexibility of the 212 series of encoders.

PIN DIAGRAM

ELECTRICAL DISCRIPTIONS

Functional Description

Operation

The 212 series of encoders begin a 4-word transmission cycle upon receipt of a transmission enable

(TE for the HT12E active low). This cycle will repeat itself as long as the transmission enable (TE or D8~D11) is held low. Once the transmission enable returns high the encoder output completes its final cycle and then stops as shown below.

Information word

If L/MB=1 the device is in the latch mode (for use with the latch type of data decoders). When the transmission

enable is removed during a transmission, the DOUT pin outputs a complete word and then

stops. On the other hand, if L/MB=0 the device is in the momentary mode (for use with the momentary

type of data decoders). When the transmission enable is removed during a transmission, the DOUT

outputs a complete word and then adds 7 words all with the _1_ data code.

An information word consists of 4 periods as illustrated below.

COMPOSITION OF INFORMATION

HT12D

Features

_ Operating voltage: 2.4V~12V _ Low power and high noise immunity CMOS technology

_ Low standby current _ Capable of decoding 12 bits of information

_ Binary address setting _ Received codes are checked 3 times

_ Address/Data number combination _ HT12D: 8 address bits and 4 data bits

_ Built-in oscillator needs only 5% resistor _ Valid transmission indicator

_ Easy interface with an RF or an infrared transmission medium

_ Minimal external components _ Pair with Holtek_s 212 series of encoders

_ 18-pin DIP, 20-pin SOP package

Applications

_ Burglar alarm system _ Smoke and fire alarm system

_ Garage door controllers _ Car door controllers

_ Car alarm system

_ Security system _ Cordless telephones

_ Other remote control system

General Description

The 212 decoders are a series of CMOS LSIs for remote control system applications. They are paired with Holtek_s 212 series of encoders (refer to the encoder/decoder cross reference table). For proper operation, a pair of encoder/decoder with the same number of addresses and data format should be chosen. The decoders receive serial addresses and data from a programmed 212 series of encoders that are transmitted by a carrier using an RF or an IR transmission medium. They compare the serial input data three times continuously with their local addresses. If no error or unmatched codes are found, the input data codes are decoded and then transferred to the output pins. The VT pin also goes high to indicate a valid transmission. The 212 series of decoders are capable of decoding informations that consist of N bits of address and 12_N bits of data. Of this series, the HT12D is arranged to provide 8 address bits and 4 data bits, and HT12F is used to decode 12 bits of address information.

FABRICATION OF PCB

The printed circuit board(PCB) provides the electrical interconnections various components and as well as provides mechanical support to the components.The components are soldered to the PCB.The quality of soldering directly affects the reliability of the circuit.The procedure for fabricating the PCB for any general project is described below.

¢ PCB MAKING

The making of PCB essentially involves two steps.

1.Preparing PCBdrawing

2.Fabricating PCB from the drawing.

¢ PCB Drawing

Making of PCB drawing involves placement of components , locating holes ,optimum area each componenet should occupy, shape and size of pads for the componenets , track size and spacing and prevention of overcrowding of components at a particular area. With these details the sketch of the PCB is made.

¢ PCB FABRICATION

The fabrication of the PCB starts by transferring the PCB drawing onto a copper clad sheet. For a small number of PCBs a direct photographic transfer of the PCB drawing from a negative image of the drawing to a photo sensitised copper clad sheet is carried out. The copper from the unexposed area is later etched away.

For large quantity production, screen printing method is used to transfer the PCB drawing image to the copper clad sheet. For etching the copper clad sheet 20-30grms of ferric chloride in 75ml of water heated to about 60degree celsius may be used . The copper clad sheet is placed in the solution with its copper side upwards in a plastic tray. Stirring the solution helps in speedy etching. The dissolution of unwanted copper would take about 45min. If etching takes longer, the solution may be heated again and the process is repeated. The paint on the pattern can be removed by rubbing with a rag soaked in thinner, turpentine or acetone. The PCB can then be washed and dried. The pads are drilled with proper drill sizes of 0.9mm,1mm,3mm etc for the leads and mounting holes

ASSEMBLY AND TESTING

Assembly consists of soldering of components and wires on to the PCB and mechanical fitting of wired PCB and other assemblies. Testing is carried out even at design phase itself in breadboard level to verify the design, so that little or no circuit changes are required after designing the PCB.

¢ Soldering

Before soldering, all the discrete components are tested. The leads of the components are cleaned with a fine abrasive paper. The PCB also thoroughly cleaned by scratching the areas to be soldered. The leads of the components are bend properly, inserted into the holes and placed correctly. A small quantity of flux is applied to the component leads and pads to remove the oxide coating. The leads are soldered with good quality solder with sufficient heat from the soldering iron. Excess heat will result in improper soldering and may damage the component.

All the joints are checked after the soldering.

¢ Testing

After soldering the components on to the PCB, the board is thoroughly cleaned for any residual flux and wire leads. All the components are checked for their value and for the proper orientation if applicable. Before ICs are inserted into the sockets, power applied to the board and voltages are measured at the IC power point. Power is switched off before the ICs are inserted.

SCHEDULE

1. Literature survey

2. Design of circuit

3. Testing of the circuit on breadboard

4. Modifying the circuit

5. Making pcb layout

6. Pcb fabrication

7. Soldering

8. Results obtained

CONCLUSION

Our product is suitable for bank, home and other security threat areas. Being cost effective and simple its application will be wide. Power consumption is very low which is a key feature. Many modifications can be easily implemented making it user friendly.

No comments:

Post a Comment